Part 1 Selection

First of all, due to work, I need to design a 5v 10w switching power supply, so I started a series of work. This is my work journal. This records a period of unforgettable years in the life.

The first step is always the hardest.

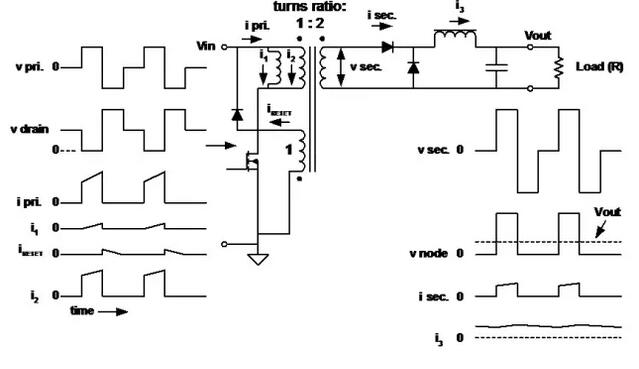

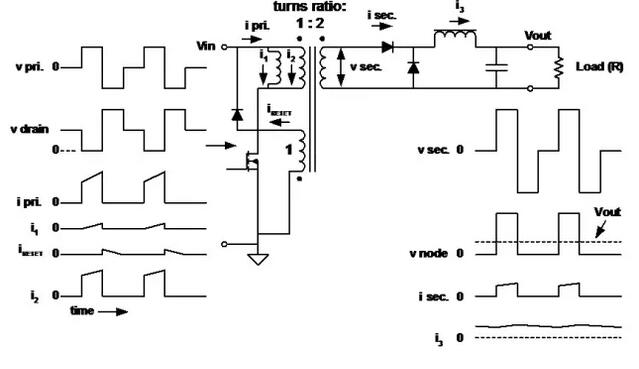

When it comes to switching power supply design, the first problem is how to choose the circuit topology. Practical uses include Forward, RCC (Ringing Choke Converter) and Flyback Converter.

Forward

Forward is also known as positive switching power supply. This circuit structure is suitable for switching power supply with relatively large power. Compared with other two circuit structures, the circuit structure is more complex and larger in volume. It costs more. It is mainly used in the switching power supply above 100w. As the power of my design is relatively small, I did not choose it.

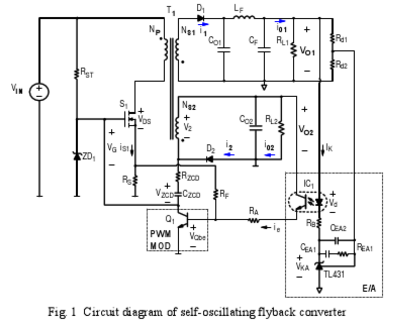

RCC(Ringing Choke Converter)

RCC(Ringing Choke Converter)

This type of design is common in low-cost designs. But its reliability and stability are hard to guarantee. But it has the advantage of low price.

Although the new MOS tube has improved many original defects of RCC circuit, it still cannot fundamentally change the fate of RCC being eliminated.

Flyback circuit

The last one I chose was the Flyback, which is actually not my choice, but the Flyback circuit has essentially cornered the market for low-power switching power supplies. Except for those extremely low-cost products will use RCC structure, now the world's formal products are selected Flyback circuit structure. I can summarize the reasons as follows.

First, small size and simple structure.

Second, low cost.

Third, high stability.

Fourth, can support wide pressure input.

I have carefully studied the advantages, in fact, the most overwhelming actually can be wide input voltage. It is important to be able to support both 110Vand 220V in areas where the voltage is unstable and for products that need to be globalized.

Further retrieval will show you that there are several categories of Flyback circuit types, depending on the type of feedback.

First, the main winding negative feedback.

This circuit is only under very low cost applications will only be used, mainly used in fixed load application, through the high voltage transformer impedance transformation to do corresponding PWM control, no help auxiliary winding. This kind of circuit is poor, but its cost is low. But I certainly can't accept such a circuit structure.

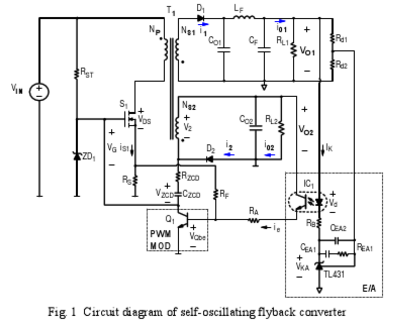

Second, the original negative feedback PSR.

This type of circuit is actually the most widely used in Flyback topologies because it is used so much. Compared with the first solution, the cost increase is very limited, but the stability and reliability have been greatly improved. So there's a lot of actual use in the market. Each supplier has its own solution. But this circuit has a fatal disadvantage over the latter two. That is, the output voltage regulation rate is low, the response is slow. Still more suitable for fixed load.

Third, the negative feedback of optocouplers.

Third, the negative feedback of optocouplers.

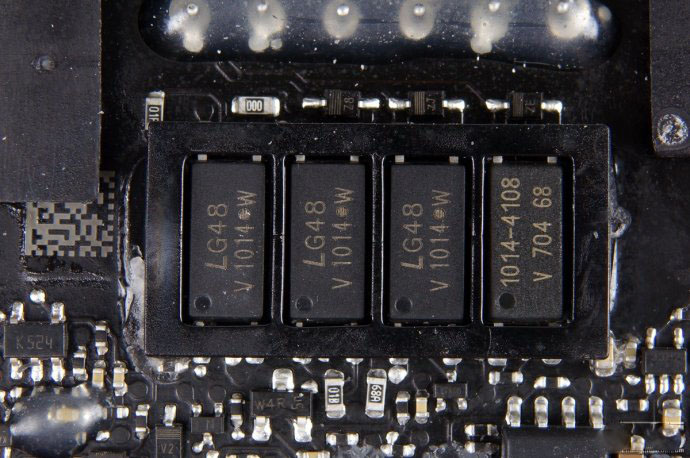

In fact, this is the textbook Flyback circuit is the correct standard solution. As long as it is a regular general products, will choose such a program to use. But it's still not perfect. Because the photocoupler will attenuate with the use time, the temperature will also affect the work of the photocoupler. Of course, there are also solutions. For example, apple's PD charger uses dual optical couplers to offset these negative applications through mutual compensation of two optical couplers.

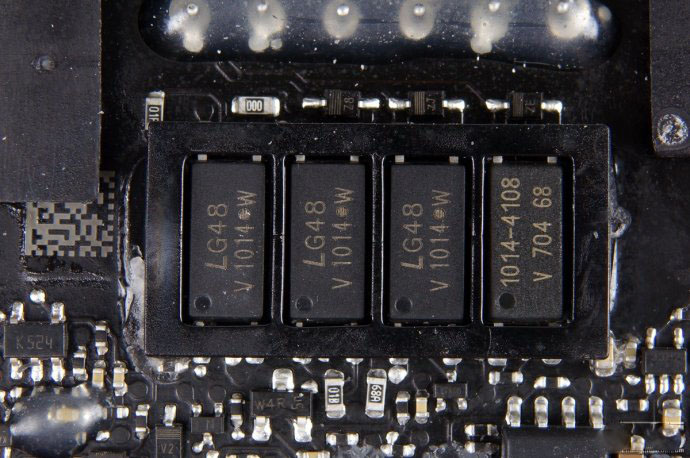

The APPLE A1719 uses a 4 optocoupler feedback scheme.

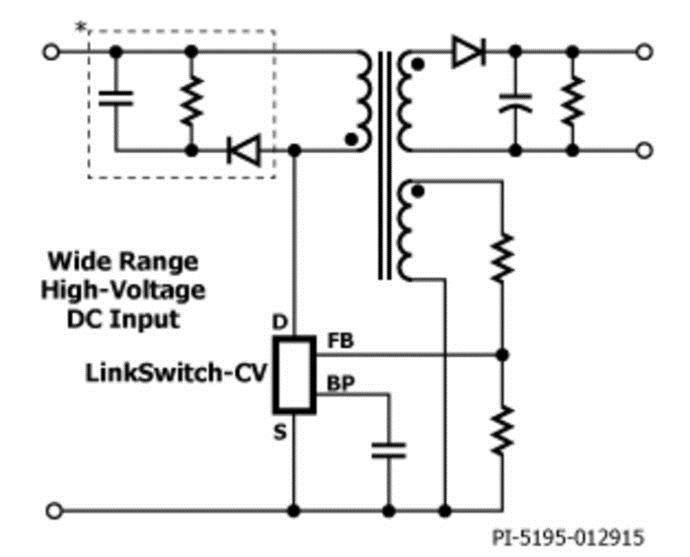

Fourth, magnetic coupling negative feedback.

Magnetic coupling is actually a very new technology. When I first learned about switching power, I had never heard of this kind of feedback. Of course, its advantages are obvious. Magnetic coupling almost solves all the disadvantages of optical coupling feedback. And it's more integrated. The number of components in bom table has been greatly reduced. I want to do the best switching power supply, if there is a suitable solution, I naturally choose the magnetic coupling.

Synchronous rectification

Synchronous rectification.

In fact, all circuits can be used synchronous rectification, but small power switching power supply with synchronous rectification or in recent years. The reason is very simple.

The thermal efficiency of the low-power switching power supply is lower than that of the high-power switching power supply, and the lower the power is, the more the efficiency will decline. In order to improve the efficiency, synchronous rectification is the best choice. If you do not choose synchronous rectification, you may lose a few components, but heat dissipation is a problem. Custom aluminum is a small thing, and the installation of heat sink is not an easy thing, so synchronous arrangement in the small power switch power supply is increasingly used.

Quasi Resonant PWM control

Quasi Resonant PWM control

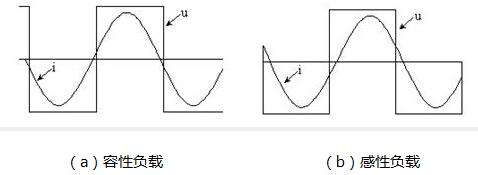

In order to improve the efficiency of switching power supply, there is the technology of passing zero switch through the phase stagger of circuit such as inductance and capacitance. However, quasi - resonant control does not have the complex inductance - capacitance configuration of traditional standard resonant circuit. The zero current switch is easily implemented. This has made a qualitative leap in improving the efficiency of traditional low-power switching power supply. Combined with synchronous rectification technology, the latest scheme can even improve the efficiency of low-power switching power supply to more than 94%. That's an amazing number.

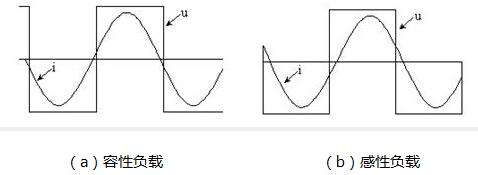

(a) Capacitive load (b)Inductive load

(a) Capacitive load (b)Inductive load

Stagger current and voltage to realize zero power switch.

It may be reasonable and logical that everything has changed like this now, but in fact it was not like this at the beginning. Everything is difficult at the beginning.

There are many solutions of small switching power supply and many suppliers. The market is very chaotic. Each supplier has numerous sub-products. How to choose a model is actually a matter. No one is going to help you until you join the club. When your company is not large enough, no original FAE is willing to help you design the switching power supply. (I saw that the original FAE directly gave some large companies like Kohler free drawing board design.)Our company does not have such strong bargaining power.

In my case, I had to study hard and work hard. Step by step. Although slow, but I am confident that I do now is the best thing, every little thing I slowly know why. You can't beat me.

What I do is to understand the mainstream AC-DC scheme in the market through the charger disassembly article on the website of charging head.

The first step, to determine the small power switching power supply 99% of Flyback is used.

In the second step, it is confirmed that the negative feedback of optical coupling is the main stream, and the negative feedback of magnetic coupling has been popularized.

Third, check to see if there is a mainstream PWM controller vendor. This step needs to be explained in detail. I have collected a series of switch power supply schemes selected by mainstream manufacturers on the market for your reference only.

Look at what everybody USES on market first.

APPLE uses the A1540 29W solution

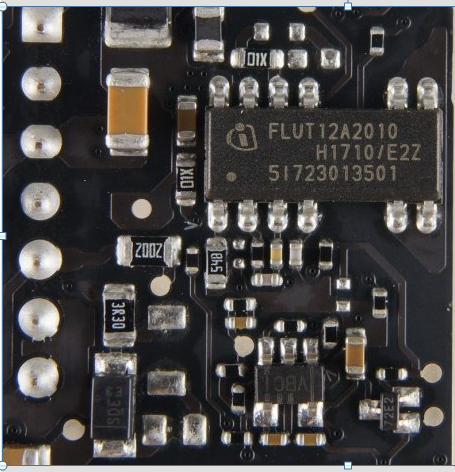

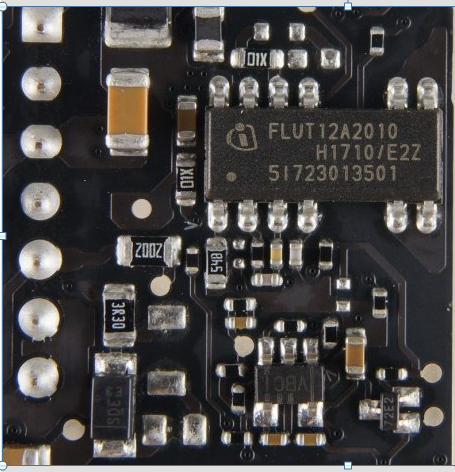

Infineon FLUT12A2010

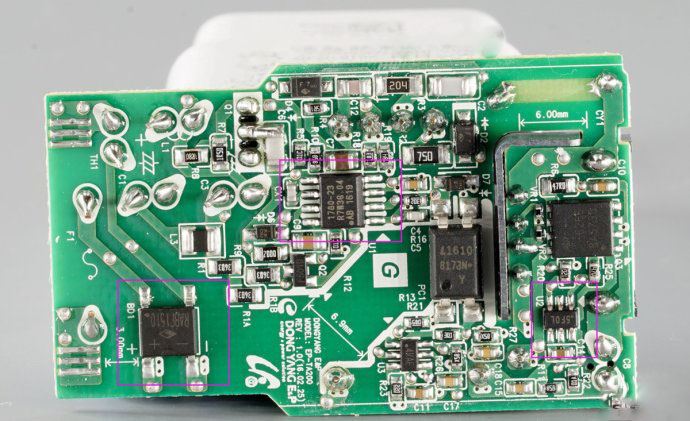

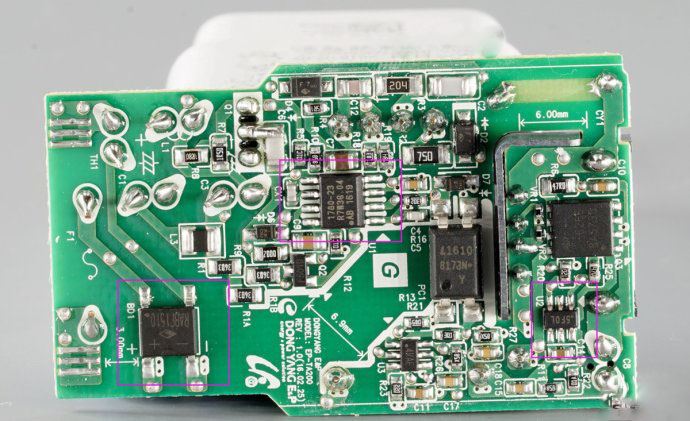

Samsung EP-TA200 charger

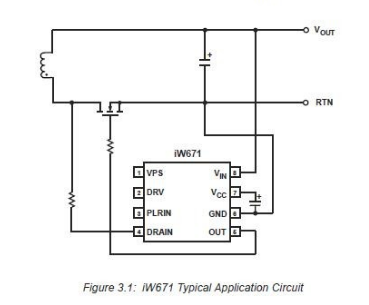

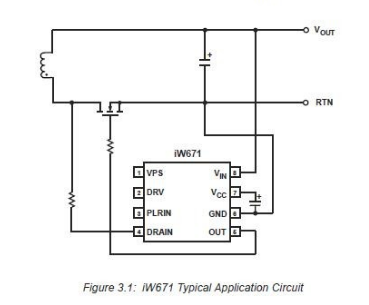

Dialog's PWM controller iW1780 synchronous rectifier controller iW673

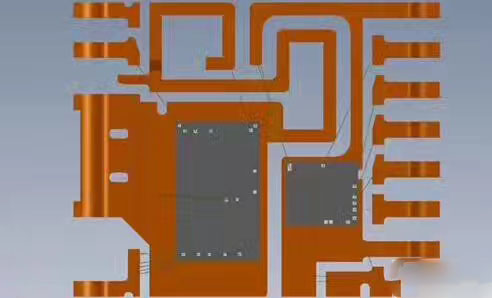

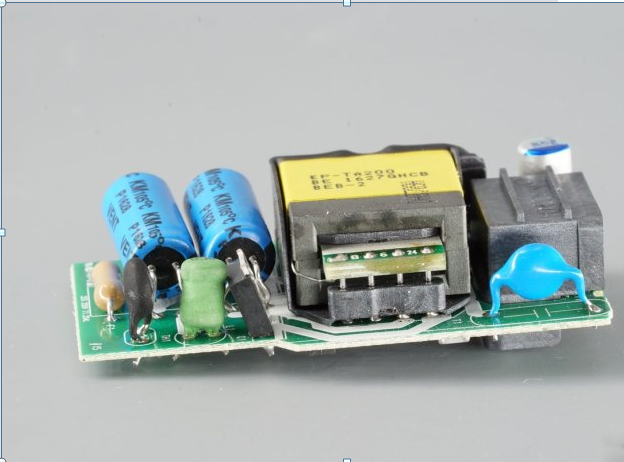

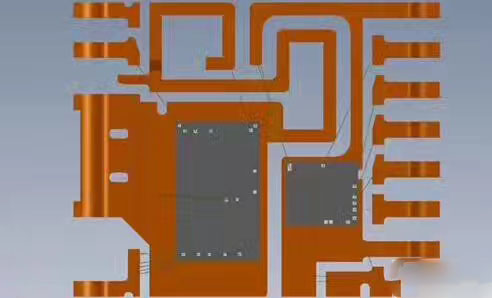

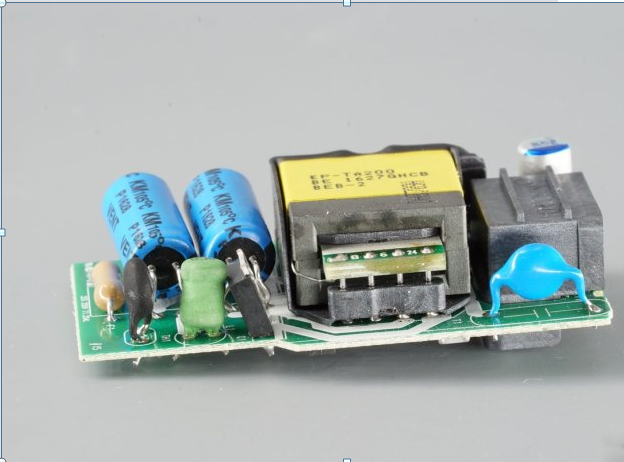

PCB planar transformer. This is rare in the common scheme of senior goods, with high consistency, stable and reliable characteristics.

Huawei HW-059200CHQ charger

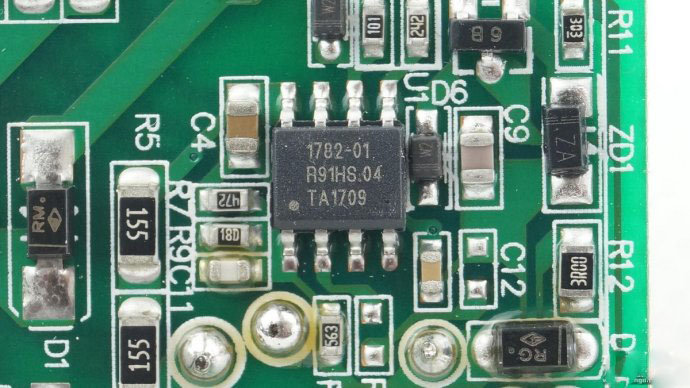

Dialog iW1780

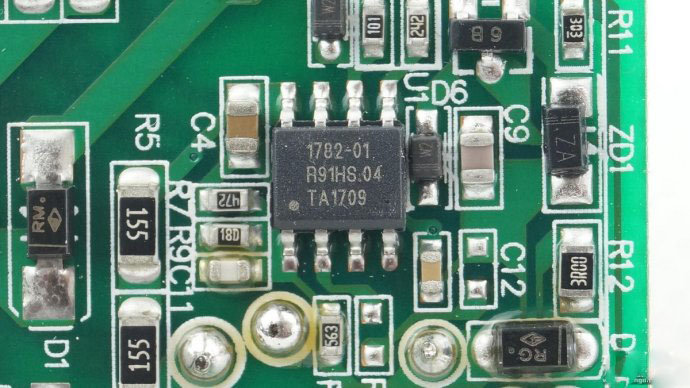

Hammer, CD101 charger

Dialog iW1782 notes that the controller is not a Flyback PWM controller, but a Quasi Resonant (QR) PWM. Quasi resonant duty ratio modulation controller with the function of zero - crossing switch.

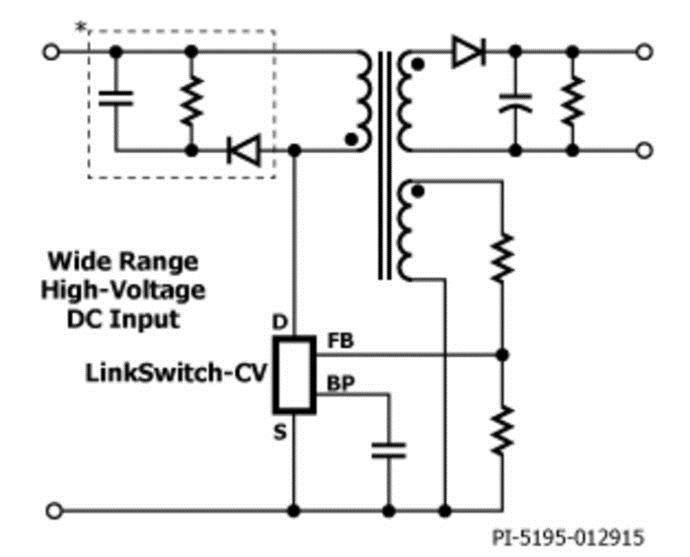

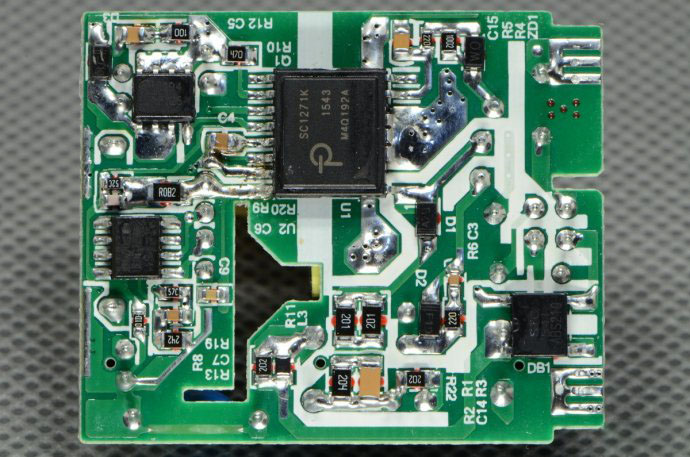

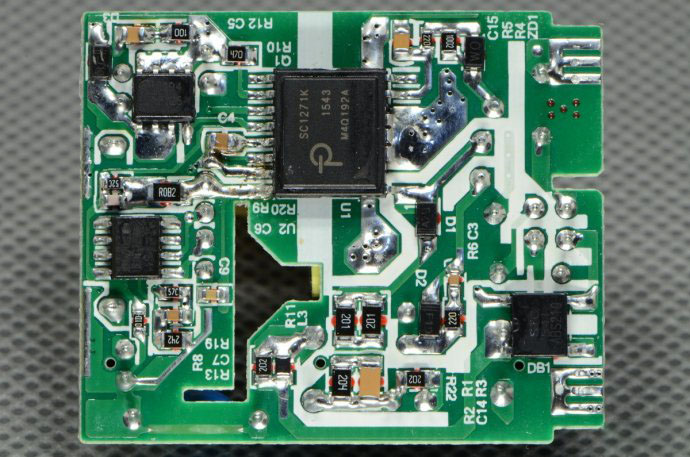

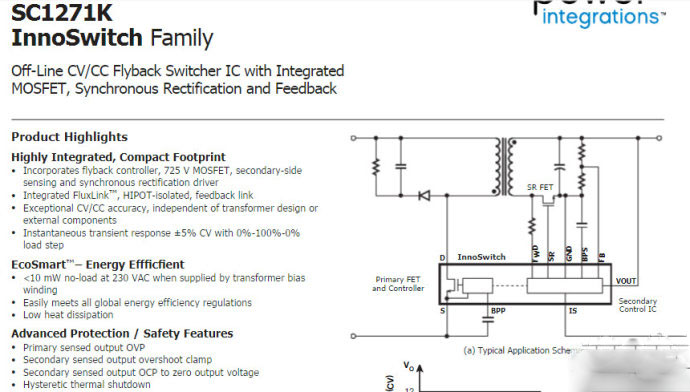

Millet 5 charging head MDY-08-EH

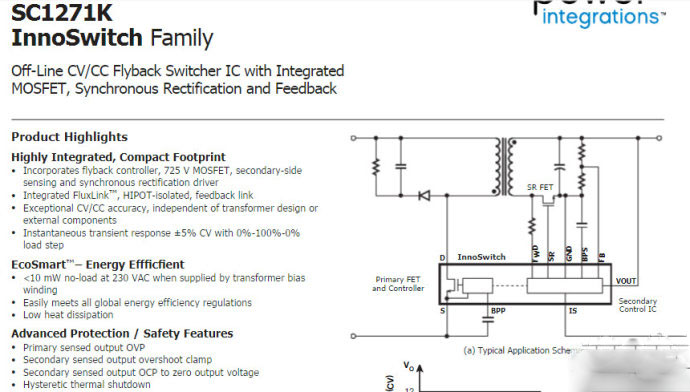

The latest innoswitch 2 solution with power integrations

Absolute top chip, single chip integrated synchronous rectification, magnetic coupling negative feedback technology, this is in the whole industry is outstanding. It was not until later that I realized that this controller is not a traditional PWM control, but a control mode called "ON OFF". That is to say the frequency is not fixed. Full intelligent pulse control.

The great ones I saw were dialog-semiconductor and power integrations. Both are very distinctive.

Dialog-semiconductor, with its powerful digital control capability, has achieved a high degree of reliability and is able to respond quickly and numerically to sudden changes. So the largest customer base, and QR quasi resonance can greatly improve the switching efficiency of switching power supply. Power integrations with magnetic coupling, integrated synchronous rectification, fewer BOM components and more compact volume. So I decided to go with power integrations and it just spiralled out of control.

Before entering the industry, I always thought that an AC DC controller can be used for many years, but in fact, the whole industry is around the latest energy standards and constantly launch new products. The reason is simple: higher and higher energy standards. It forces manufacturers to update their technology to meet the latest eu standards. For the whole earth to contribute to energy conservation and environmental protection. QR and synchronous rectification technology is also for this reason, now more and more applications. In fact, it can be said that these years of switching power technology is far from the textbooks can be learned.

After that, I'll write about other switching power supply. We are

MICRO POWER ELECTRONICS (HK) CO., LIMITED, mainly engaged in Power Supply customization, including 5V ,12V , 24V , 5W to 1500W Power Supply, AC/DC Power Supply, 24v power supply, switch mode power supply, 12v switch power supply,

switching power supply design, 48v dc power supply, 24v switching power supply, smps power supply and High Power :1200w - 500kW. AC and DC Power Supply. If you are interested in, you can visit our official website at

micropowerchina.com.

Request A Quote

Request A Quote